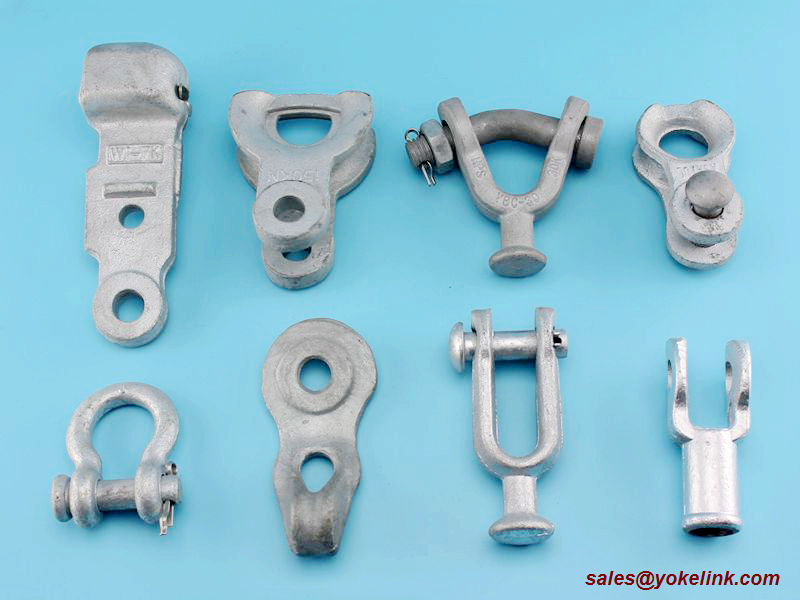

The sliding bearing is in surface contact, so a certain oil film should be maintained between the contact surfaces. Therefore, the following problems should be noted in the design: 1. The oil film can smoothly enter the friction surface. 2. The oil should enter the bearing from the non-bearing surface area. 3. Do not open the full ring oil groove in the middle of the bearing. 4, such as oil tiles, open the oil groove at the seam. 5, to make the oil ring oil is fully reliable. 6. Do not block the oil hole. 7. Do not form an oil-free zone. 8. Prevent sharp edges and corners from cutting off the oil film. Transmission hardware fittings are components used in the construction and maintenance of transmission lines for electricity or telecommunications. These fittings are designed to connect, support, and secure the different parts of the transmission line, ensuring proper functioning and reliability. Yokelink supply a full line of Tower hardwares, , provide part number to get a quote on these products, leave your message, or send us an email to get answers for your questions or product you needed. Socket Eyes are used for connecting conductor clamping devices to ball and socket type insulators. Made by malleable iron, hot dip galvanized to meet ASTM A153 specification. Ball Eyes are used to attach ball and socket insulators to other associated hardware. Hot dip galvanized to meet ASTM A153 specification. Thimble Cleivs are used for attaching guy to pole eye plate. Hot dip galvanized to meet ASTM A153 specification. Turnbuckles are used as adjustable extension links to maintain proper tower clearance on assemblies at tower end. Strain Clamp used for distribution and transmission line construction with all aluminum ACSR, or aluminum alloy conductor. Transmission Hardware Fitting, Socket,Ball eye, Hot line, Chain Link, Turnbuckle, Suspension, Strain, Yoke plate,malleable iron,hardware,tower,links Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com

Some common types of transmission hardware fittings include:

Suspension Clamps: Used to hang the conductors from the transmission towers, providing support and preventing sagging.

Dead-end Clamps: Used to terminate the conductors at the ends of the transmission line, providing support and preventing them from slipping.

Splice Sleeves: Used to join two conductors together, ensuring a secure and conductive connection.

Insulators: Used to electrically isolate the conductors from the transmission towers, preventing electrical leakage and ensuring proper insulation.

Guy Wire Fittings: Used to secure and stabilize the transmission towers, preventing them from swaying or collapsing.

Connectors: Used to connect different components of the transmission line, such as conductors, insulators, and fittings, ensuring a secure and reliable connection.